Research and Development at OPTEC:

Leading Innovation in Optical Systems Design

At OPTEC, we specialize in cutting-edge research and development (R&D) in optical systems, offering unparalleled expertise for space, defense, commercial, and medical applications.

Our R&D process ensures precision, reliability, and performance excellence, underpinned by a comprehensive, phased approach:

- 1. Feasibility Phase

- 2. Design Phase

- 3. Optical Simulations and Advanced FE Analyses

- 4. Validation and Verification Phase

- 5. Test Prescription and Arrangements

1 FEASIBILITY PHASE

The journey begins with a thorough assessment of the project's goals, constraints, and technical requirements. This phase involves:

- Concept Exploration: Evaluating innovative optical designs and emerging technologies.

- Requirement Analysis: Collaborating with clients to establish clear performance, environmental, and operational specifications.

- Preliminary Simulations: Utilizing advanced modeling tools to assess potential system performance and technical risks.

- Risk Assessment: Identifying challenges related to materials, manufacturing, and integration while proposing mitigation strategies.

Outcome: A comprehensive feasibility report outlining the technical path forward, expected performance benchmarks, and project viability.

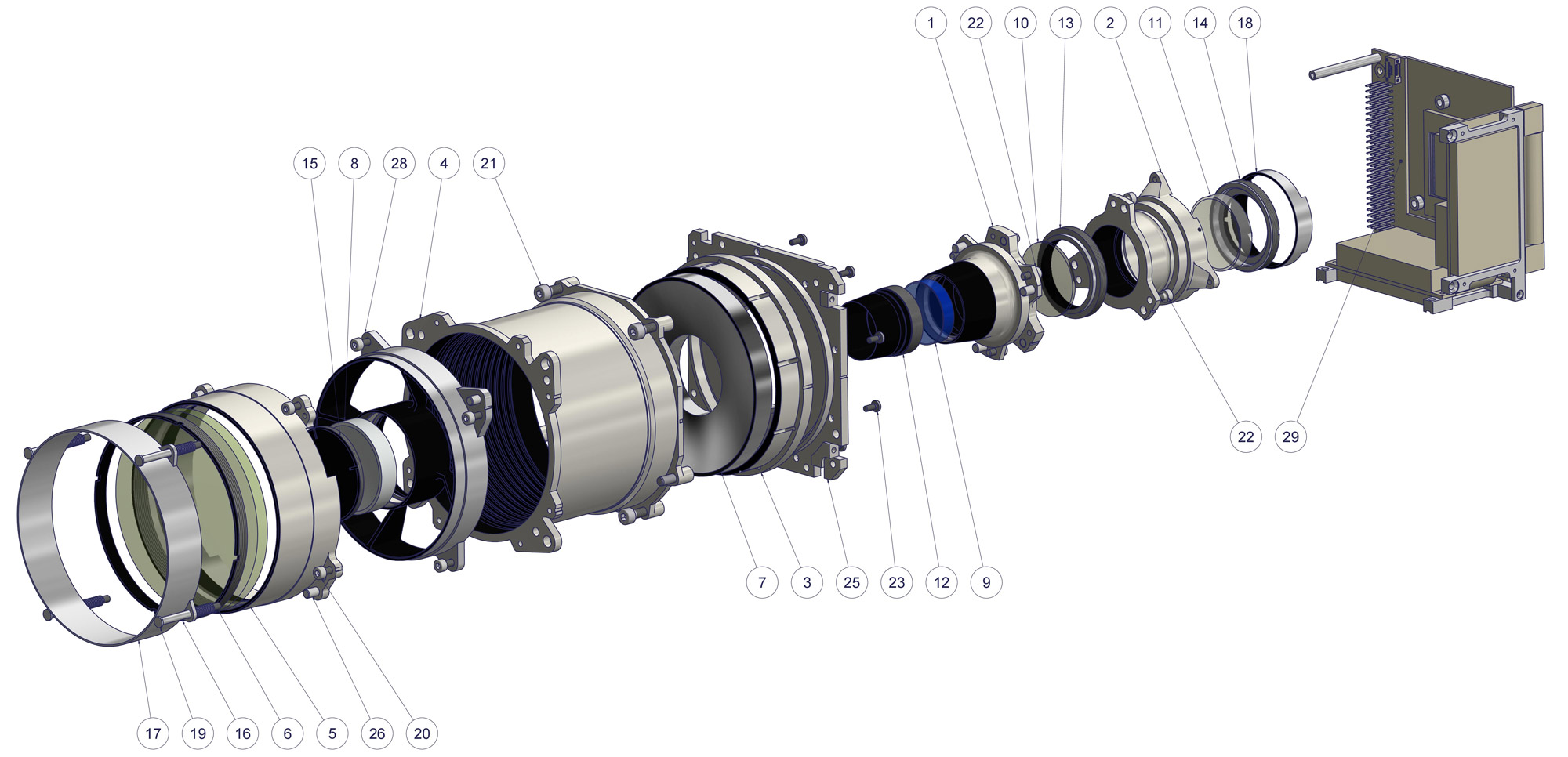

2 DESIGN PHASE

This phase transforms feasibility studies into actionable designs, focusing on innovation, precision, and alignment with customer needs.

- System Architecture Development: Creating detailed blueprints for optical, mechanical, and electronic components.

- Iterative Prototyping: Employing rapid prototyping and computational analysis to refine designs.

- Material and Component Selection: Choosing optimal materials to ensure performance in harsh environments, such as space or military operations.

- Integration Strategy: Designing for seamless integration with existing systems or frameworks.

Outcome: A robust, optimized design ready for validation and verification.

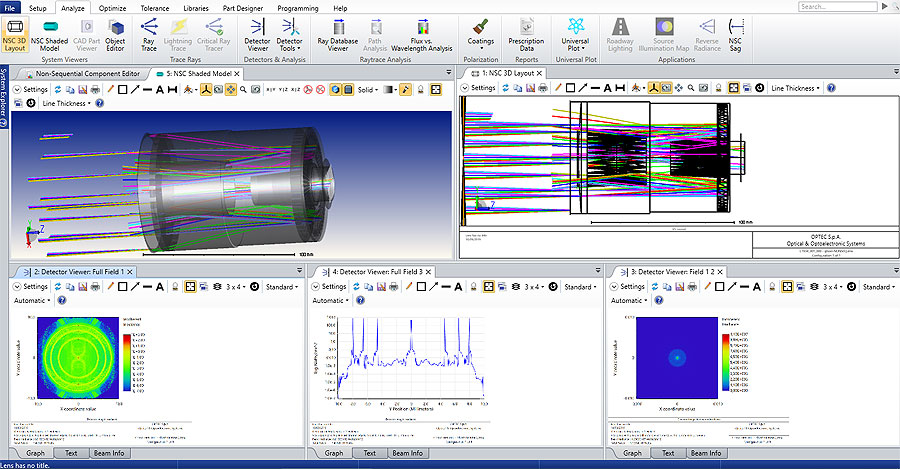

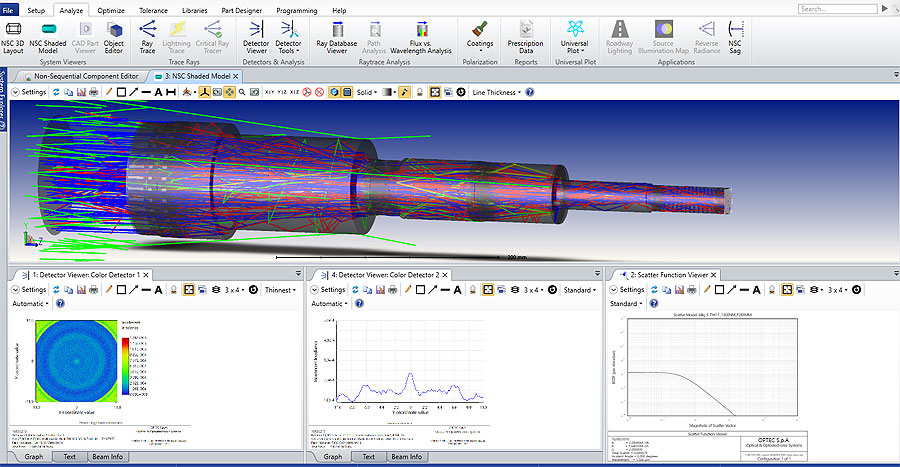

3 OPTICAL SIMULATIONS AND ADVANCED FE ANALYSES-

To ensure the design’s robustness and functionality, OPTEC leverages state-of-the-art simulation and analysis techniques.

- Optical Simulations: Employing high-fidelity ray tracing and wavefront analysis to predict and optimize system performance under varying conditions.

- Straylight Analysis: Minimizing unintended light scatter to enhance system efficiency and ensure clear, accurate imaging or detection.

- Finite Element Structural Simulations: Assessing mechanical stability under static and dynamic loads, ensuring resilience in extreme operational environments.

- Thermo-Elastic Simulations: Evaluating the effects of thermal expansion and contraction on optical performance, critical for space and high-temperature applications.

- STOP Analysis (Structural-Thermal-Optical Performance): Integrating structural, thermal, and optical factors to ensure optimal performance under real-world conditions.

Outcome: Comprehensive insight into system performance, enabling preemptive adjustments and risk mitigation before physical prototyping.

4 VALIDATION AND VERIFICATION PHASE

Ensuring the system meets all functional, performance, and regulatory requirements is central to OPTEC’s V&V phase.

- Model Validation: Comparing simulation results with empirical data to verify theoretical models.

- Performance Testing: Evaluating system behavior under various conditions, such as temperature extremes, vibrations, or radiation.

- Compliance Verification: Ensuring designs adhere to industry standards, including ISO, MIL-STD, and FDA requirements, depending on the application.

- Iterative Refinement: Addressing discrepancies or deficiencies to optimize system performance.

Outcome: A validated design that has been rigorously tested to meet and exceed all expectations.

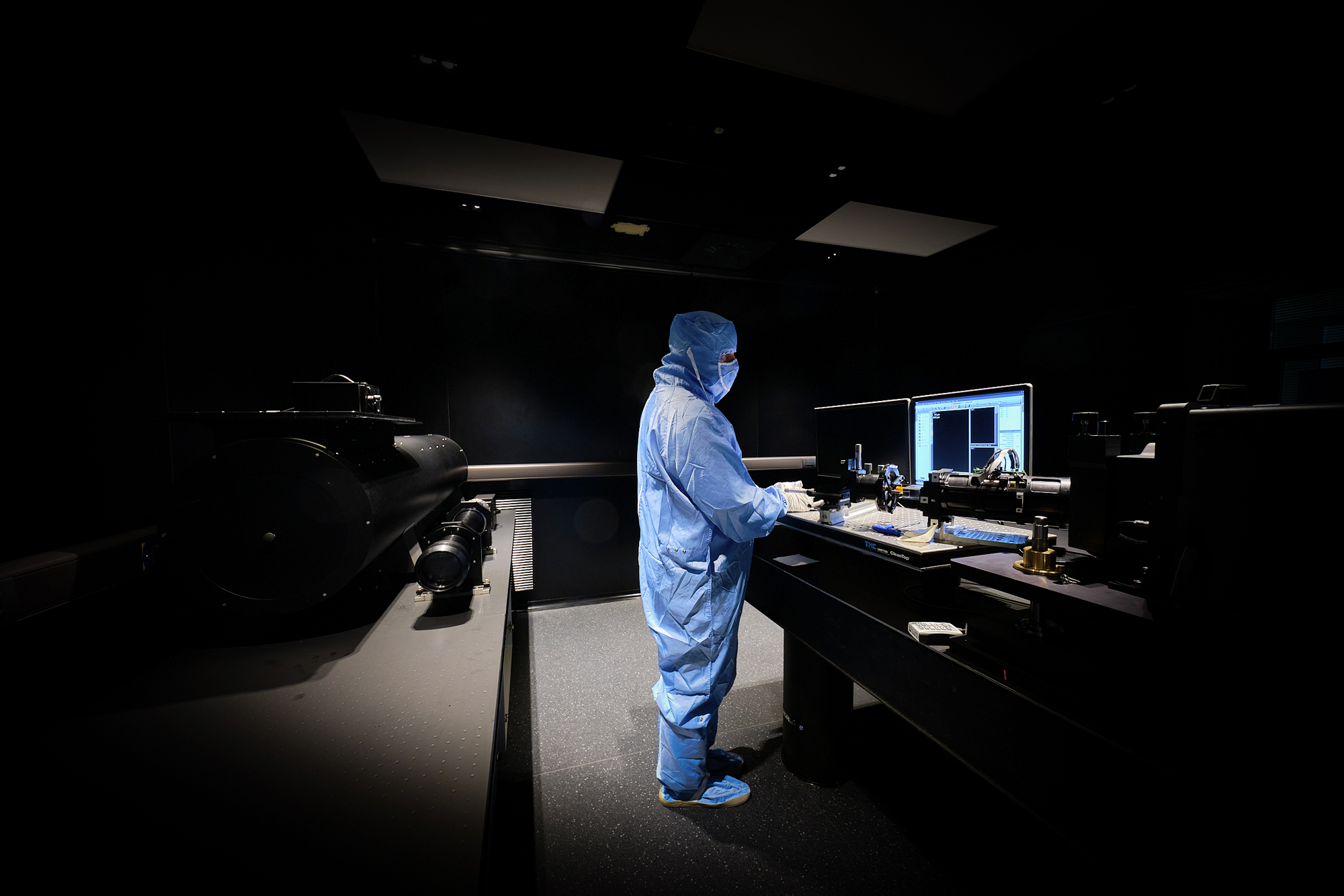

5 TEST PRESCRIPTION AND ARRANGEMENTS

OPTEC’s expertise extends to defining, organizing, and conducting comprehensive test programs:

- Test Planning: Developing detailed protocols to evaluate optical performance, durability, and reliability.

- Custom Test Facilities: Leveraging state-of-the-art labs and simulation environments tailored to specific needs, including vacuum chambers, thermal testing, and precision metrology.

- End-to-End Testing: Covering component-level evaluations to full system integration tests.

- Collaborative Execution: Working closely with stakeholders during testing phases to ensure alignment with mission objectives.

Outcome: A thoroughly tested and validated optical system, ready for deployment in critical applications.

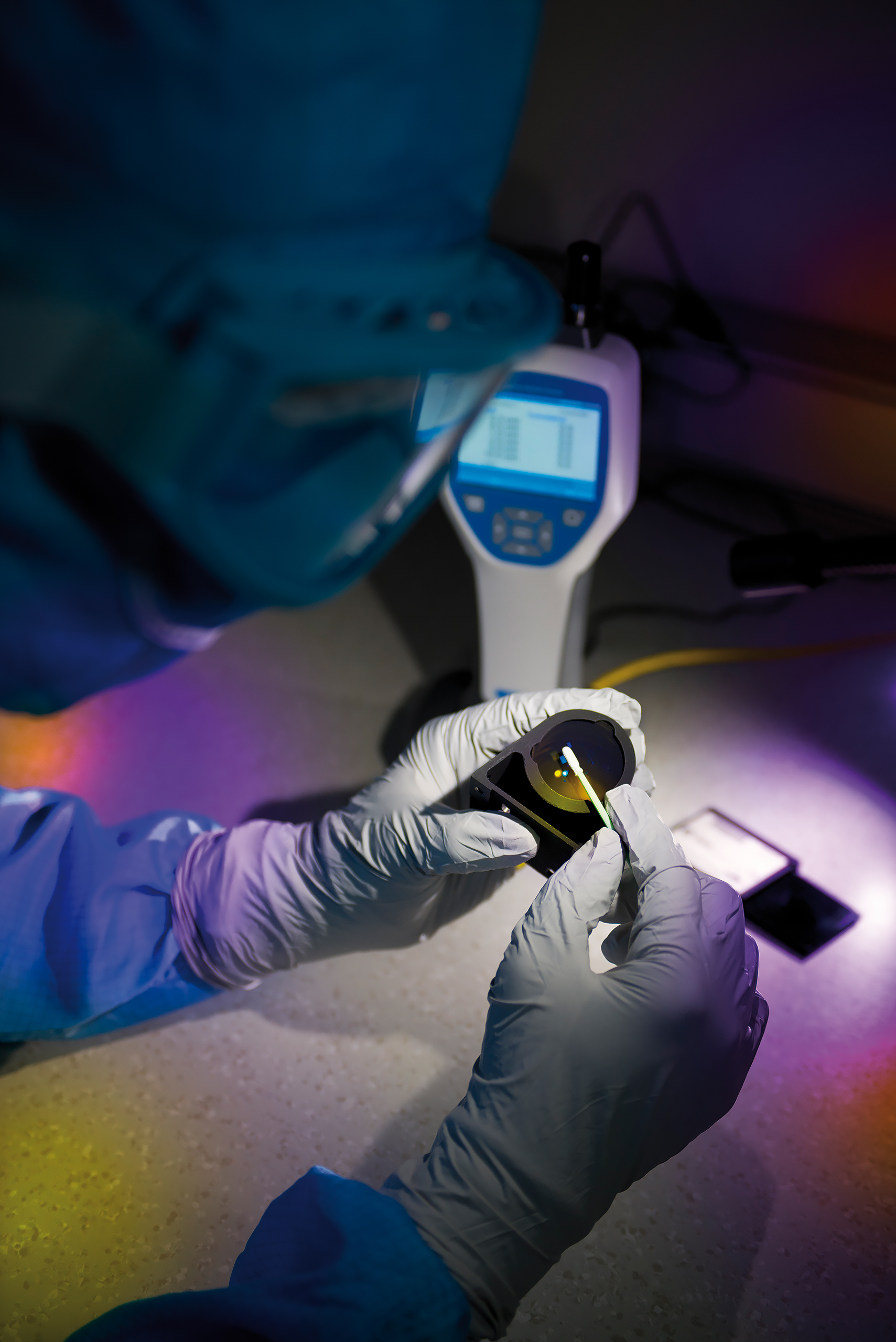

Testing, Calibration and Straylight Analysis

Optec is a leader in providing comprehensive testing, calibration, and straylight analysis services for optical components and systems. With a commitment to precision and innovation, Optec ensures that every system meets the most demanding industry and research standards.

Feel free to contact Us

Get in touch with us

Credits: NMI