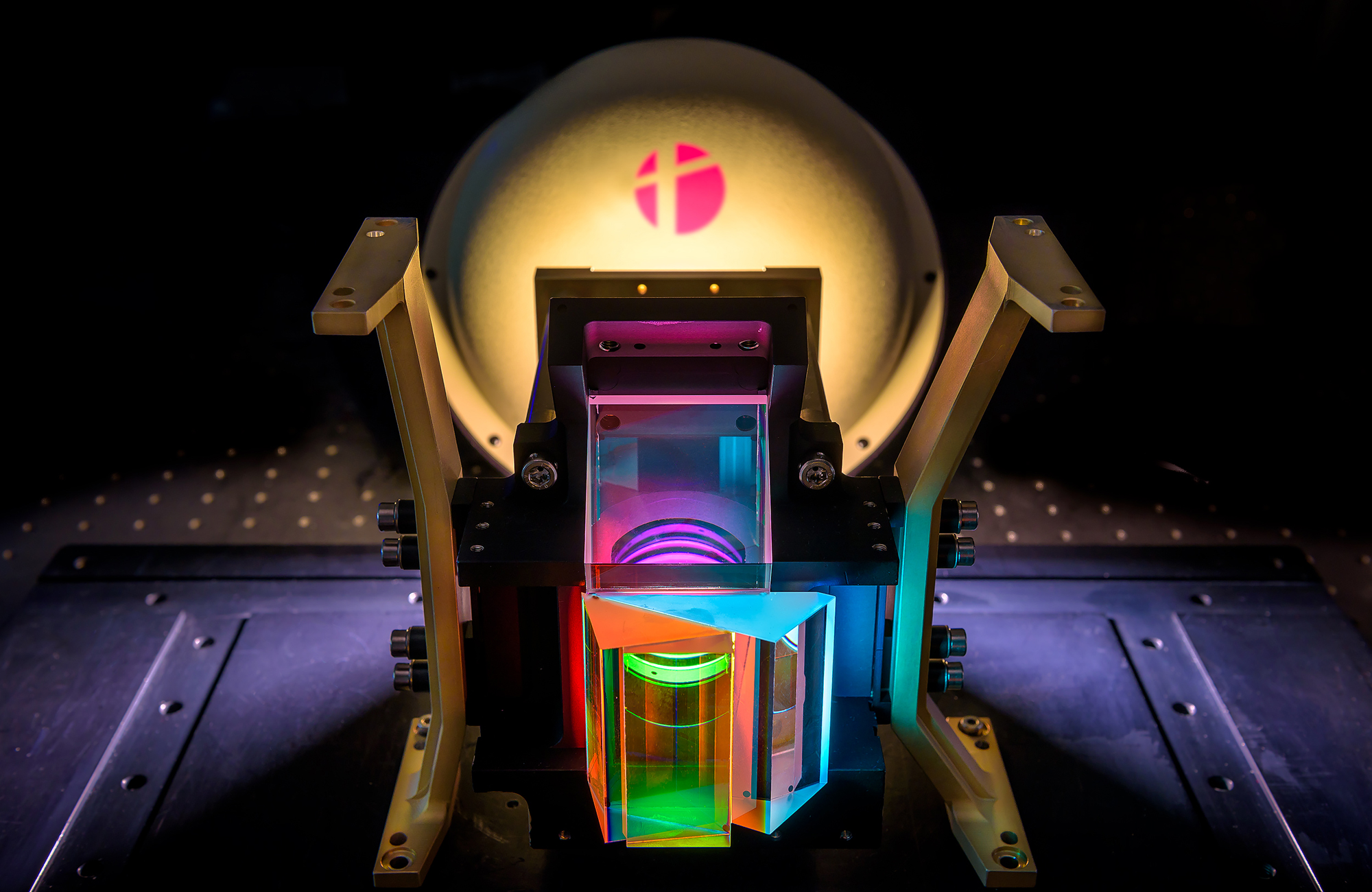

Optec: Leading Space, Defense and Innovation

Services

Consulting

Optec provides to its customers a variety of consulting services

Discover

COC

RMA

Warranty on Optec SpA products is 12 months, as stated in the sale general conditions.

Click here for Optec SpA Return Material Authorization procedure

Feel free to contact Us

Get in touch with us

Copyright © 2025 Optec S.p.A. Optical & Optoelectronic Systems. All rights reserved.

Credits: NMI

Credits: NMI